by Bill Hedrick

One thing that makes America a world leader is how private industry steps up to the plate during a national crisis. During WWII, the Ford Motor Company and others retooled their manufacturing lines to produce airplanes, jeeps, and other goods to fuel the war effort. It is the trademark of a country where everyone bans together to fight a common enemy.

Fighting the war that is called COVID-19 is no different. Once again, private industry is doing what they can to defeat this menacing adversary. In fact, the government has asked manufacturers capable of producing protective equipment for the medical community to do so without FDA approval during the COVID-19 crisis.

Full Color, a photo lab in Dallas, Texas, has been serving professional photographers since 1978. But, as the COVID-19 began spreading throughout the country, Full Color and other “non-essential” businesses were forced to close their production lines. Even so, they wanted to help in some way. After hearing countless news reports about the shortages of medical supplies, Full Color’s President, Steve Pullin, came up with a way to make use of some of their equipment to help with the shortage of personal protective equipment.

In mid-February, Full Color installed a special router for cutting aluminum for custom shapes and larger sizes to expand their (popular) Metal Print product line. After hearing about other companies retooling to create new products for the medical industry, Steve Pullin quickly realized how this machine was the perfect tool for creating a disposable face shield for medical personnel.

In mid-February, Full Color installed a special router for cutting aluminum for custom shapes and larger sizes to expand their (popular) Metal Print product line. After hearing about other companies retooling to create new products for the medical industry, Steve Pullin quickly realized how this machine was the perfect tool for creating a disposable face shield for medical personnel.

While most of the shields currently use an elastic headband, Steve designed this one as a single piece with the foam attached because the demand for the elastic has already depleted the supply in this country. The router, which would have been completely idle during this pandemic, could be put to good use. In less than 5 minutes, it could quickly cut out a full sheet of shields, allowing for quick packaging and shipment.

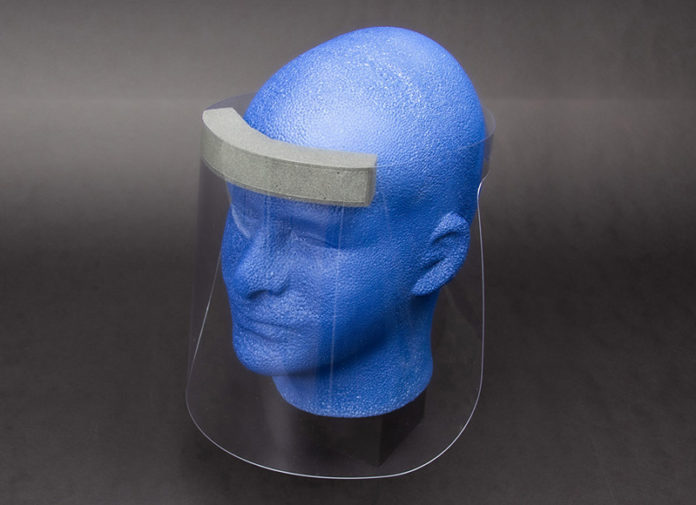

The concept evolved very quickly. In just a few days, Full Color and their consultants had finalized a design and sourced both the thermoplastic from Allied Plastics of Dallas, and the foam from another source they used for their USB tins. In no time, the product was being sold and was featured on their website. The shields are a “one-size-fits-most” solution to the need for a physical barrier between the wearer and potential chemical or respiratory hazards and are intended for anyone who needs them.

The Disposable Face Shields are sold in packages of 10 and the only assembly required is to attach the foam headband. Each shield measures 8 1/2 x 13 inches and ia made of .02 inch VIVAK® transparent thermoplastic with an adjustable, slide and tuck, tab. Service time is normally two to three days.

So far, their sales have been to health centers and nursing homes and their reach has been through Facebook via people in the medical community. However, anyone who wants to do something for their local medical community doesn’t have to look any further than Full Color Lab. A package of 10 Disposable Face Shields is only $64.90 with discounts for larger quantities. To view and/or to order these Disposable Face Shields, go to www.fullcolor.com/disposable-face-shield.html.